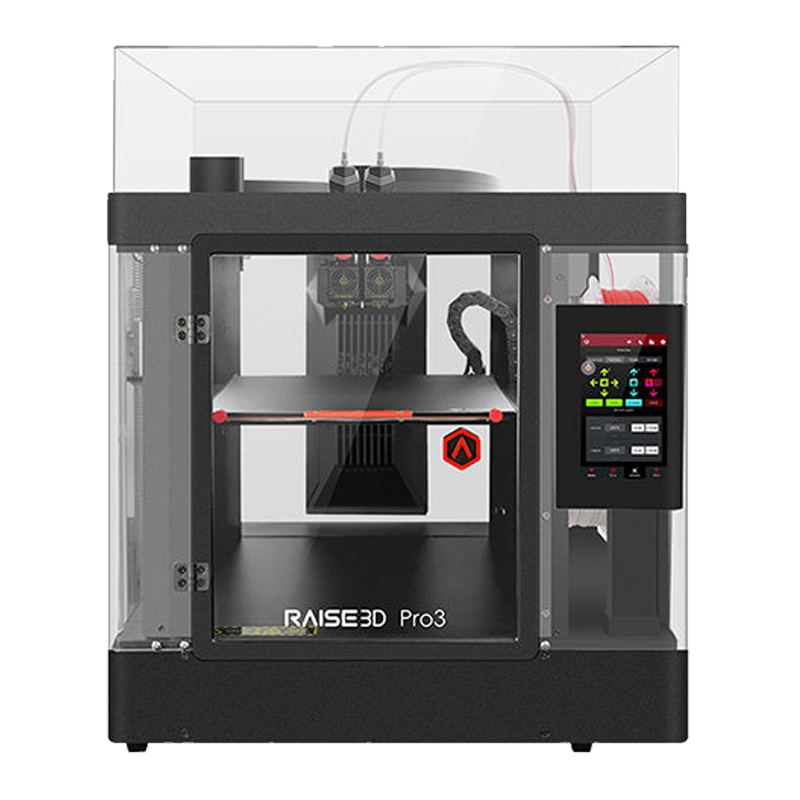

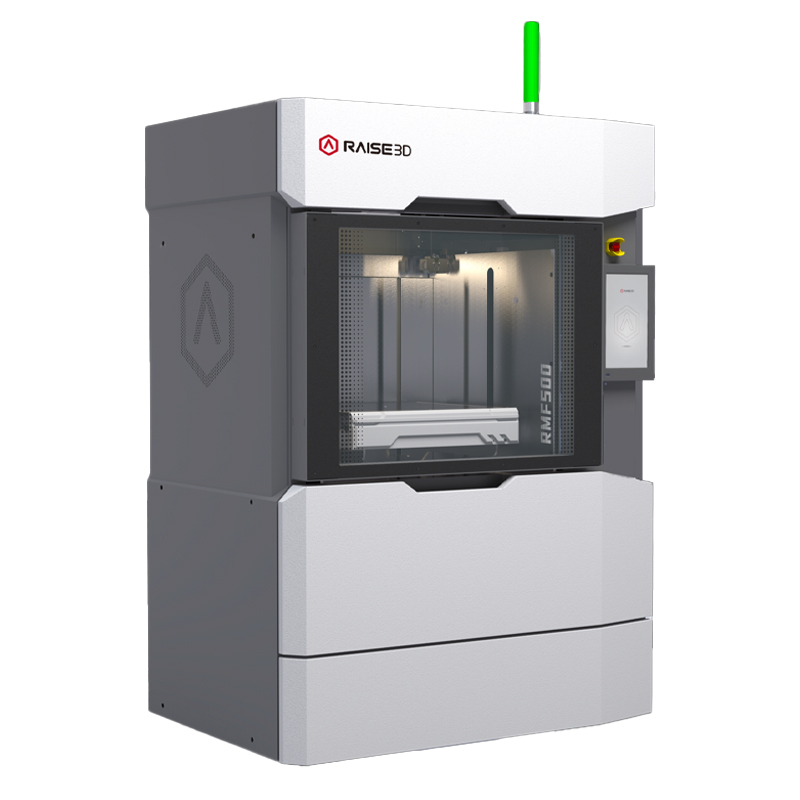

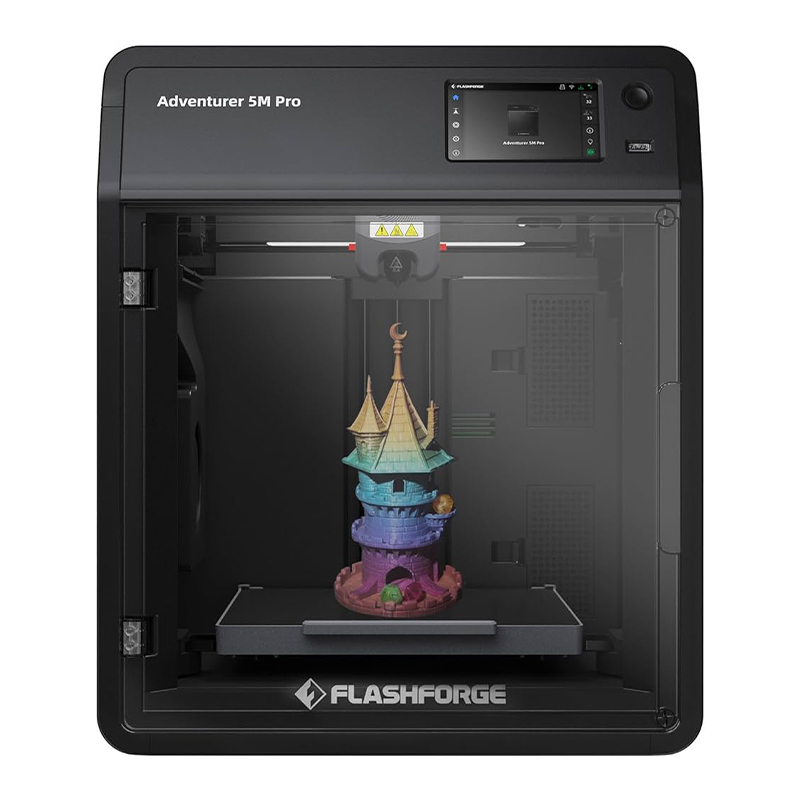

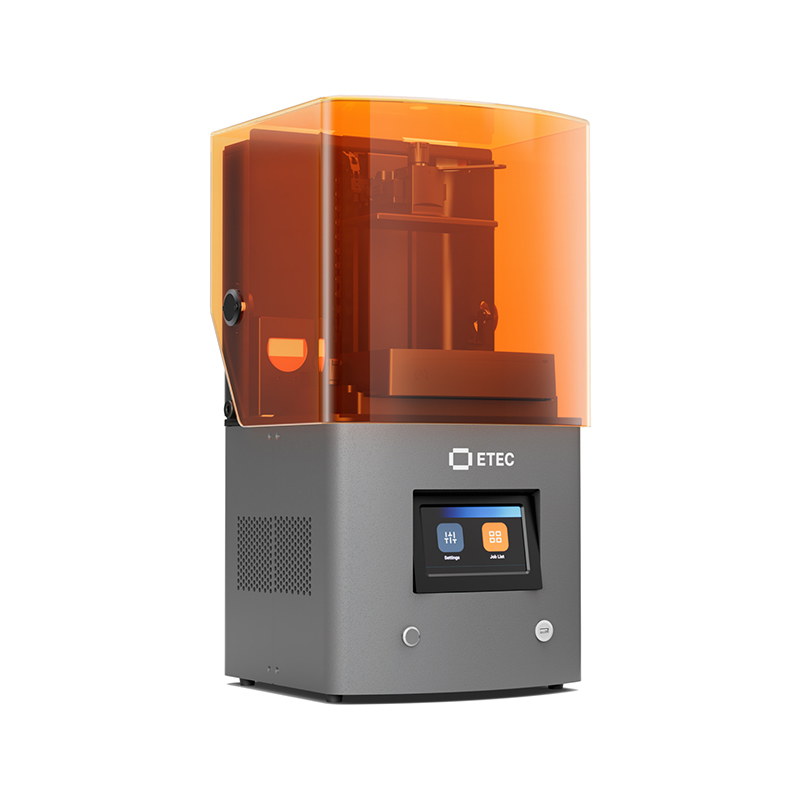

3D Printers offered by Beckatt Solutions

3D printing, or additive manufacturing, is a manufacturing process that creates a physical object from a digital model file. 3D printers are the machines that make these three-dimensional objects by laying down successive layers of material, one layer at a time, to build up a complete object. 3D printers receive instructions on how to accomplish this through a file that is created using slicing software. The original digital model file is created using computer-aided design (CAD) or some similar software. The slicing software takes the CAD file and “slices” it into thin layers that the printer can build up, layer by layer.

3D printing traces its origin to the 1980s, when it was originally known as ‘rapid prototyping’. Rapid prototyping enabled companies to develop prototypes quickly and more accurately than with other methods. After 30 years of invention and innovation, 3D printing’s uses are far more diverse today. Manufacturers, engineers, designers, educators, health care professionals and hobbyists all use the technology for a large range of applications. The development of more compact and affordable 3D printers has made the technology much more accessible over time.

There are many different types of 3D printers and 3D printing technologies, and most operate using some form of FDM/FFF (fused deposition modeling/fused filament fabrication), SLA/DLP (stereolithography/digital light processing) or SLS (selective laser sintering), though this is not an exhaustive list of technologies. The most common types of 3D printers use spools of thermoplastics, called filament in the FDM process. The filament is heated to a molten state and extruded through a nozzle, building up layer upon layer of material to create the object.

3D printers are used in a wide range of industries and applications, from prototyping to product development to manufacturing uses and even end-use parts. 3D printing is also used to make architecture models, education and medical models, parts that go in space, in food production and much more. 3D printers are a valuable tool for educators, engineers, designers and the like in helping to create complex and highly detailed 3D objects with unique structures and a high level of precision. 3D printers have the opportunity to revolutionize many industries by enabling rapid design and testing, customization and small-scale production that was too expensive or too slow previously.

Learn MoreMore About 3D Printers

3D printing, or additive manufacturing, is a manufacturing process that creates a physical object from a digital model file. 3D printers are the machines that make these three-dimensional objects by laying down successive layers of material, one layer at a time, to build up a complete object. 3D printers receive instructions on how to accomplish this through a file that is created using slicing software. The original digital model file is created using computer-aided design (CAD) or some similar software. The slicing software takes the CAD file and “slices” it into thin layers that the printer can build up, layer by layer.

3D printing traces its origin to the 1980s, when it was originally known as ‘rapid prototyping’. Rapid prototyping enabled companies to develop prototypes quickly and more accurately than with other methods. After 30 years of invention and innovation, 3D printing’s uses are far more diverse today. Manufacturers, engineers, designers, educators, health care professionals and hobbyists all use the technology for a large range of applications. The development of more compact and affordable 3D printers has made the technology much more accessible over time.

There are many different types of 3D printers and 3D printing technologies, and most operate using some form of FDM/FFF (fused deposition modeling/fused filament fabrication), SLA/DLP (stereolithography/digital light processing) or SLS (selective laser sintering), though this is not an exhaustive list of technologies. The most common types of 3D printers use spools of thermoplastics, called filament in the FDM process. The filament is heated to a molten state and extruded through a nozzle, building up layer upon layer of material to create the object.

3D printers are used in a wide range of industries and applications, from prototyping to product development to manufacturing uses and even end-use parts. 3D printing is also used to make architecture models, education and medical models, parts that go in space, in food production and much more. 3D printers are a valuable tool for educators, engineers, designers and the like in helping to create complex and highly detailed 3D objects with unique structures and a high level of precision. 3D printers have the opportunity to revolutionize many industries by enabling rapid design and testing, customization and small-scale production that was too expensive or too slow previously.