Industrial 3D Printers

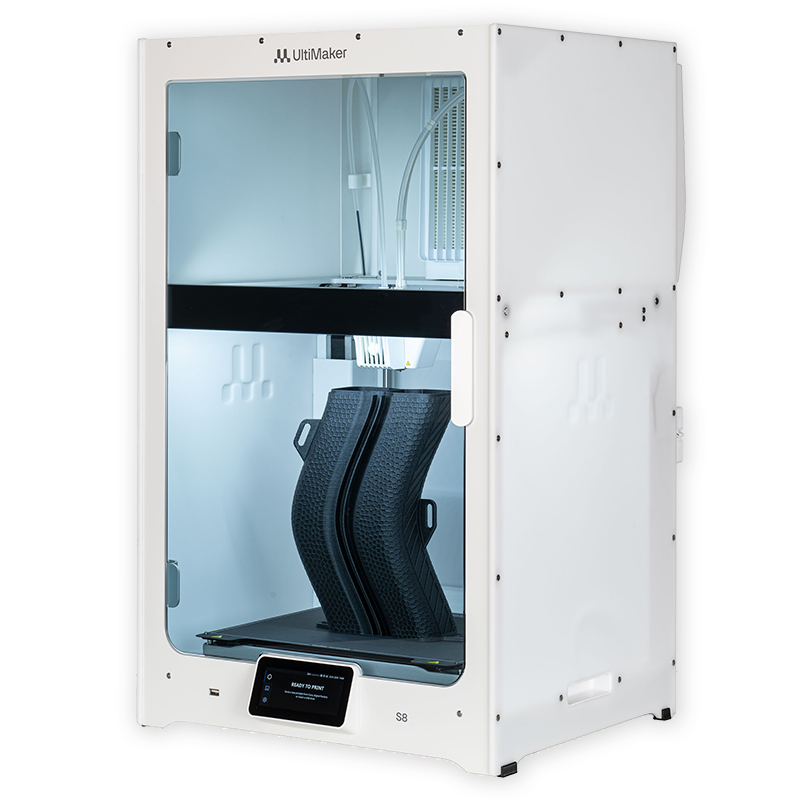

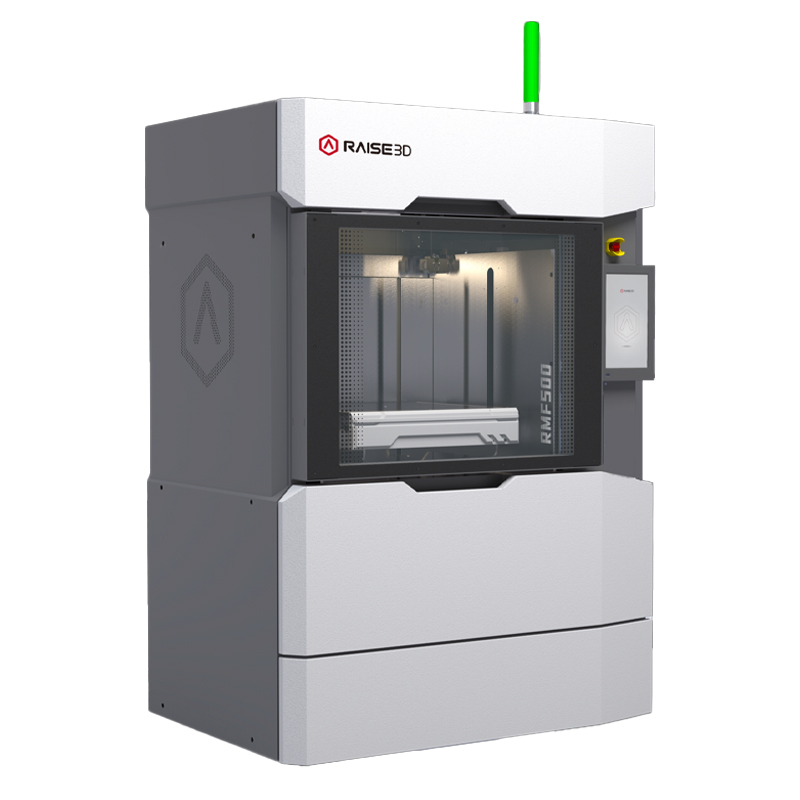

Industrial 3D printers are large-scale, high-end additive manufacturing machines that are designed for use in industrial settings, such as manufacturing, tooling and molds, aerospace, defense, medical and dental, automotive and research & development. Industrial 3D printers are typically larger, more expensive and more capable than both desktop and professional 3D printers. They can produce larger, more robust and more complex parts with a much greater degree of precision and accuracy.

Industrial 3D printers as a group use a range of additive manufacturing technologies, including SLA (stereolithography), DLP (SLS (selective laser sintering) and FDM (metal fused deposition modeling), as well as more advanced technologies such as BMD (bound metal deposition), binder jetting and DMLS (direct metal laser sintering). These technologies enable industrial 3D printers to create more robust and complex parts in a variety of materials, including industrial-grade plastics, metals, ceramics and resins.

Although parts made on desktop and professional 3D printers can be used in an industrial setting, there are several key factors that differentiate true industrial 3D printers from their counterparts. For starters, industrial 3D printers can work with very high-performance and engineering-grade materials. These materials typically have robust mechanical properties or advanced features such as heat deflection, chemical resistance or electrostatic dissipation. Parts made on industrial 3D printers can meet strict requirements that are required in an industrial setting.

Additionally, industrial 3D printers often have much larger build chambers that enable very large 3D printed parts to be created. Large build chambers, in conjunction with high speed, high repeatability and reproducibility, allows for a higher rate of productivity that will deliver parts quickly and with minimal errors. In addition to material selection, size and capabilities, industrial 3D printers allow for the creation of extremely complex parts that have a high degree of precision and dimensional accuracy.

There are numerous other factors that make an industrial 3D printer truly industrial (such as high reliability, low maintenance, advanced hardware and software components, real-time monitoring and feedback and more). Industrial 3D printers are the most advanced and powerful additive manufacturing machines we offer at Beckatt Solutions. They are a critical tool for many industries and applications that require sturdy, precise and high-quality parts at scale. Industrial 3D printers are also the most complex printers, and thus require a deep understanding of the capabilities of this equipment. Our team will work with you to fully understand your application, experience and needs and so we can offer the best industrial 3D printer for your organization.

Learn MoreMore About Industrial 3D Printers

Industrial 3D printers are large-scale, high-end additive manufacturing machines that are designed for use in industrial settings, such as manufacturing, tooling and molds, aerospace, defense, medical and dental, automotive and research & development. Industrial 3D printers are typically larger, more expensive and more capable than both desktop and professional 3D printers. They can produce larger, more robust and more complex parts with a much greater degree of precision and accuracy.

Industrial 3D printers as a group use a range of additive manufacturing technologies, including SLA (stereolithography), DLP (SLS (selective laser sintering) and FDM (metal fused deposition modeling), as well as more advanced technologies such as BMD (bound metal deposition), binder jetting and DMLS (direct metal laser sintering). These technologies enable industrial 3D printers to create more robust and complex parts in a variety of materials, including industrial-grade plastics, metals, ceramics and resins.

Although parts made on desktop and professional 3D printers can be used in an industrial setting, there are several key factors that differentiate true industrial 3D printers from their counterparts. For starters, industrial 3D printers can work with very high-performance and engineering-grade materials. These materials typically have robust mechanical properties or advanced features such as heat deflection, chemical resistance or electrostatic dissipation. Parts made on industrial 3D printers can meet strict requirements that are required in an industrial setting.

Additionally, industrial 3D printers often have much larger build chambers that enable very large 3D printed parts to be created. Large build chambers, in conjunction with high speed, high repeatability and reproducibility, allows for a higher rate of productivity that will deliver parts quickly and with minimal errors. In addition to material selection, size and capabilities, industrial 3D printers allow for the creation of extremely complex parts that have a high degree of precision and dimensional accuracy.

There are numerous other factors that make an industrial 3D printer truly industrial (such as high reliability, low maintenance, advanced hardware and software components, real-time monitoring and feedback and more). Industrial 3D printers are the most advanced and powerful additive manufacturing machines we offer at Beckatt Solutions. They are a critical tool for many industries and applications that require sturdy, precise and high-quality parts at scale. Industrial 3D printers are also the most complex printers, and thus require a deep understanding of the capabilities of this equipment. Our team will work with you to fully understand your application, experience and needs and so we can offer the best industrial 3D printer for your organization.