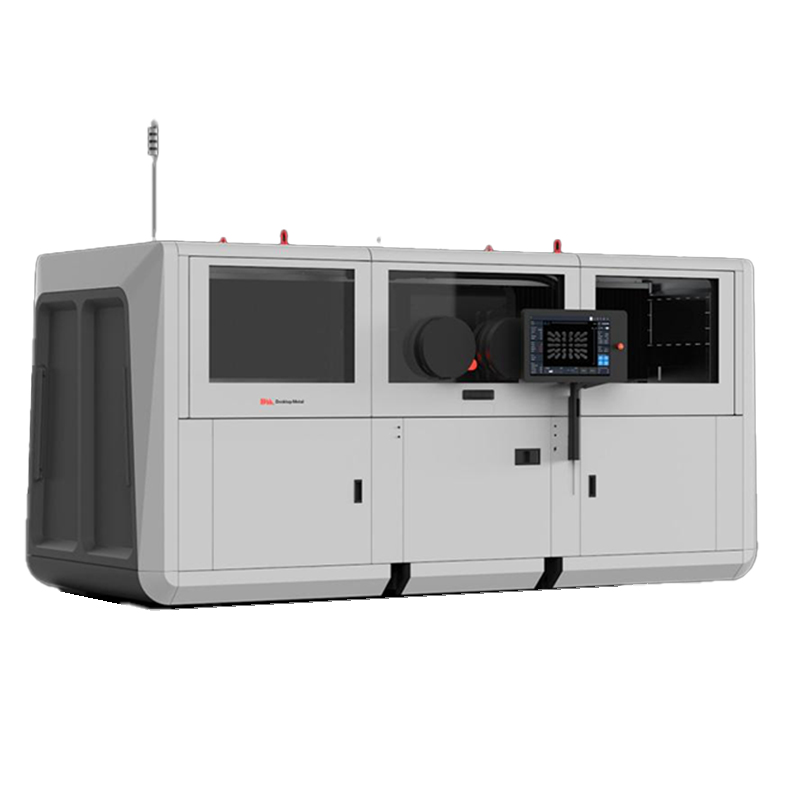

Desktop Metal Production System

Desktop Metal Production System™

High-Speed Metal 3D Printing for Mass Production

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System™ is designed to be the fastest way to 3D print metal parts at scale.

Powered by Single Pass Jetting™, the Production System™ features bi-directional 3D printing—so whenever there is movement, there is printing.

Production System P-1

Designed to bridge the gap between bench top development and mass production, the P-1 offers the same excellent part quality as the P-50 with enhanced process flexibility. Featuring a state-of-the-art print bar with native 1200 dpi, an inert processing environment, and Desktop Metal’s patent-pending Single Pass Jetting technology, the P-1 supports non-reactive and reactive materials at speeds more than 10 times those of laser powder bed fusion technologies⁴ and is capable of printing multiple builds per shift and direct process transfers to the P-50.

Production System P-50

Designed to be the fastest way to 3D print metal parts at-scale, the P-50 leverages Desktop Metal’s patent-pending Single Pass Jetting technology and bi-directional printing to achieve speeds up to 100 times those of laser powder bed fusion technologies⁴, producing parts in volumes and at costs competitive with conventional mass production techniques. Featuring a state-of-the-art print bar with native 1200 dpi, an inert processing environment, and constant wave spreading for print bed uniformity, the P-50 offers the quality, reliability, and economics required for high-volume, end-use applications.

The Production System™ delivers the speed, quality and cost-per-part needed for metal 3D printing to compete with traditional manufacturing.