3D Materials offered by Beckatt Solutions

3D printing enables users to prototype and manufacture a wide range of parts for a variety of uses, both quickly and cost-effectively. In addition to choosing the right 3D printing technology and 3D printer, choosing the right material is critical to the success of a 3D print. 3D printing has a wide choice of 3D printing materials with various material properties. With the correct material, a user can be confident that their 3D print will come out successful and meet the needs of their application.

3D printers can use a variety of materials depending on the specific technology and type of 3D printer that is used. The material selection is further narrowed down by the intended application and printing capability of the desired material. Different materials each have their own unique properties and qualities that make them best suited to specific use cases. Below are some common materials used in 3D printing.

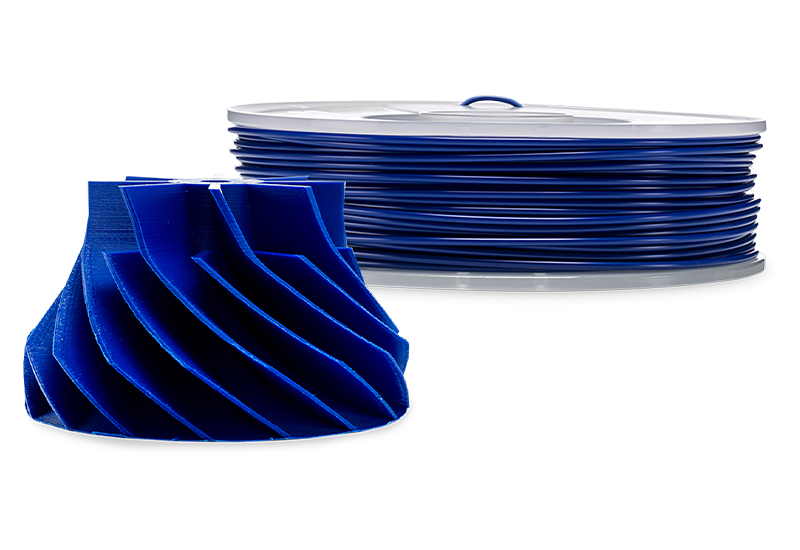

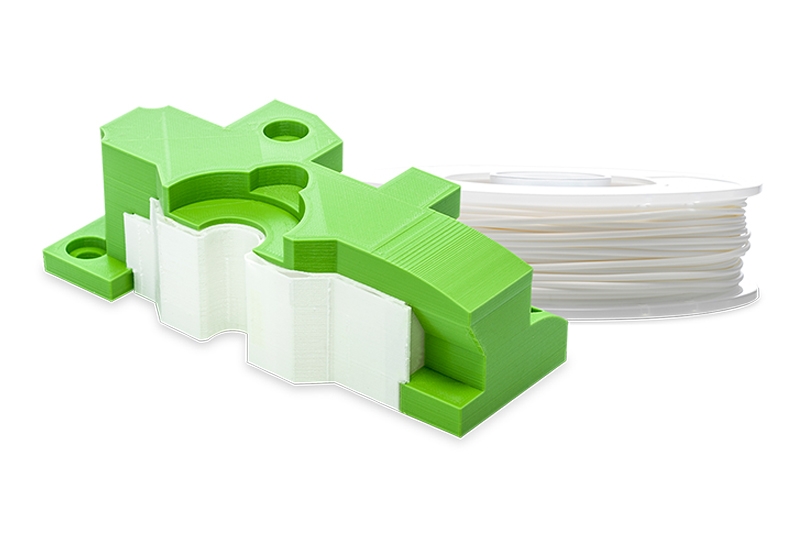

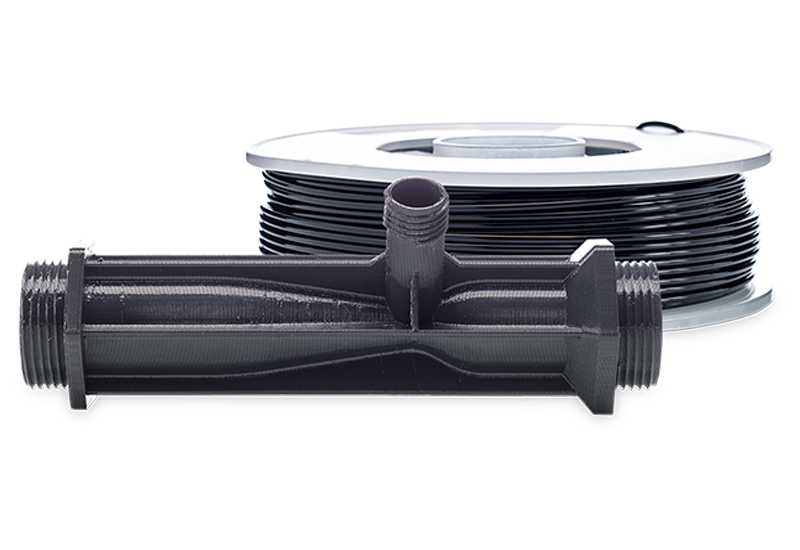

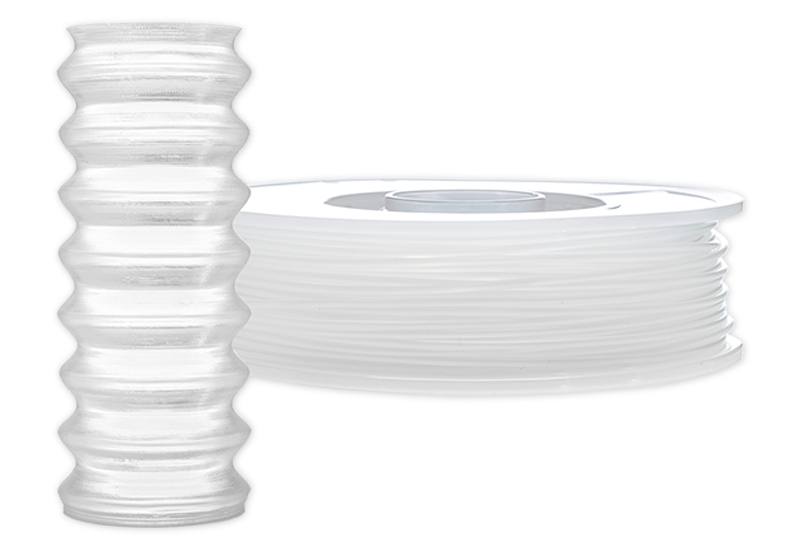

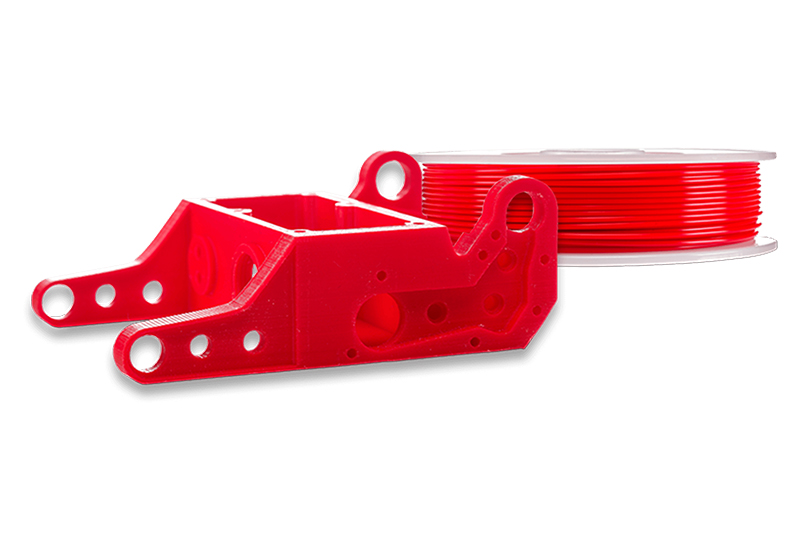

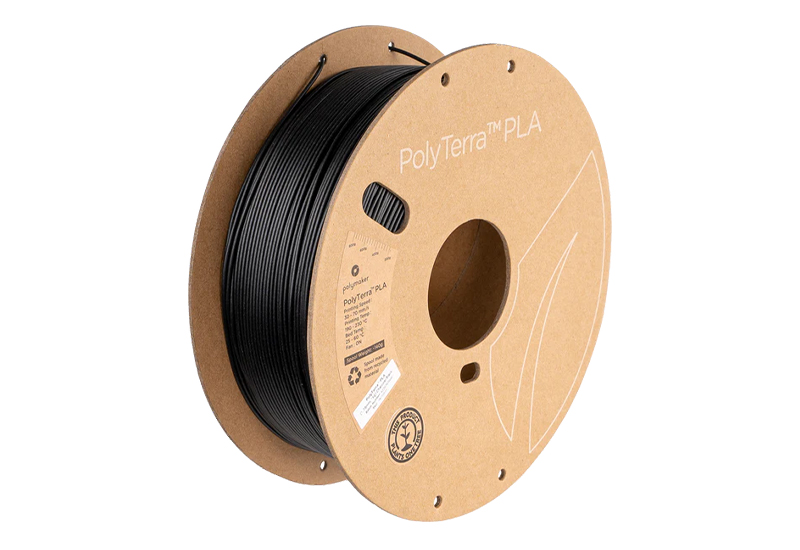

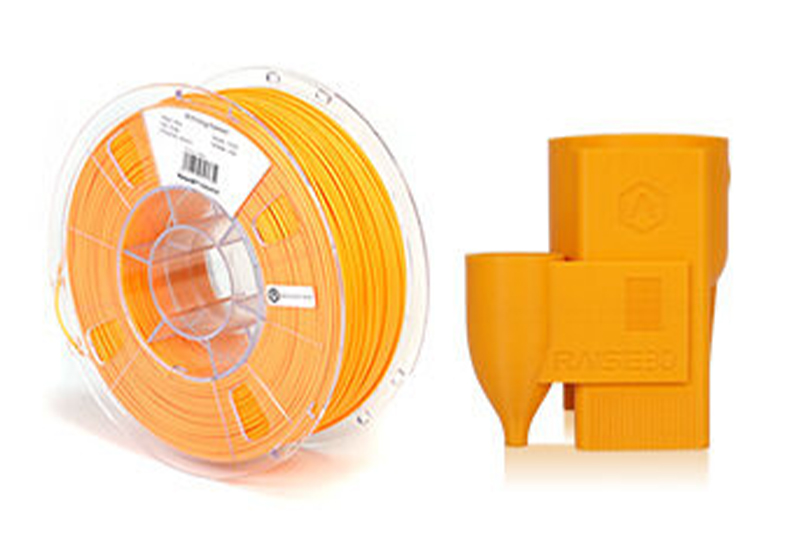

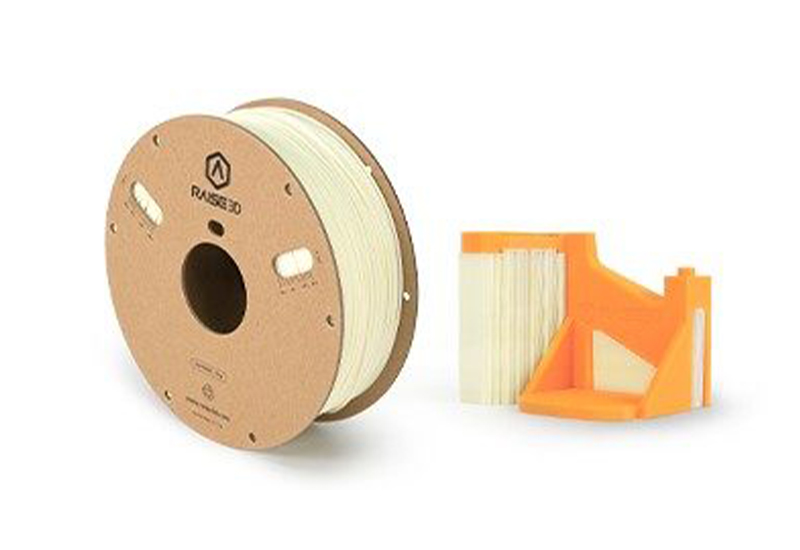

Thermoplastics are the most common type of material used in 3D printing, as they are used predominantly in the FDM process. Materials like PLA, ABS and PETG are heated and extruded through a nozzle to create the object. More advanced materials in this category include polypropylene, TPU, nylon and polycarbonate.

The first 3D printing materials, resins, are still widely used today in both SLA and DLP printing processes. Resins are liquid photopolymers that are cured using a UV laser or UV light to create the layers of the object. Resins produce the highest resolution and most accurate 3D printed parts with the best details and finest surface finish.

Another commonly used material in 3D printing are the plastics used in SLS. Most SLS printers use powdered nylon plastic that is some form of synthetic polymer. The powder is spread in the build chamber and the molecules of the material are fused together using the heat through a laser. SLS materials are not as diverse as those used in FDM and SLA, but they provide distinct advantages over these two such as isotropic strength in the case of the former and self-supporting structures in the case of the latter. SLS materials are great for complex geometries.

A relative newcomer to the 3D printing stage, metals have started to make a name for themselves. Metals such as stainless steel, aluminum, tool steels, nickel alloys and titanium have all been adopted for additive manufacturing processes such as metal FDM, binder jetting and powder bed fusion. Metal 3D printing does require more expensive and specialized equipment, but the result is metal parts that are more complex and robust.

The materials used in 3D printing are as diverse as they are unique, while at the same time constantly evolving. New materials are constantly being developed, which opens more doors for 3D printing to make an impact in a wide range of industries. Choosing the right material for your application can be difficult. We recommend you start by looking at the performance of the printed part you hope to achieve and narrow down your list to materials that can meet these specifications. If you are struggling choosing a material, our team at Beckatt Solutions is available to help. Contact us and let us help find the best 3D printing material for your project.

Learn MoreMore About 3D Materials

3D printing enables users to prototype and manufacture a wide range of parts for a variety of uses, both quickly and cost-effectively. In addition to choosing the right 3D printing technology and 3D printer, choosing the right material is critical to the success of a 3D print. 3D printing has a wide choice of 3D printing materials with various material properties. With the correct material, a user can be confident that their 3D print will come out successful and meet the needs of their application.

3D printers can use a variety of materials depending on the specific technology and type of 3D printer that is used. The material selection is further narrowed down by the intended application and printing capability of the desired material. Different materials each have their own unique properties and qualities that make them best suited to specific use cases. Below are some common materials used in 3D printing.

Thermoplastics are the most common type of material used in 3D printing, as they are used predominantly in the FDM process. Materials like PLA, ABS and PETG are heated and extruded through a nozzle to create the object. More advanced materials in this category include polypropylene, TPU, nylon and polycarbonate.

The first 3D printing materials, resins, are still widely used today in both SLA and DLP printing processes. Resins are liquid photopolymers that are cured using a UV laser or UV light to create the layers of the object. Resins produce the highest resolution and most accurate 3D printed parts with the best details and finest surface finish.

Another commonly used material in 3D printing are the plastics used in SLS. Most SLS printers use powdered nylon plastic that is some form of synthetic polymer. The powder is spread in the build chamber and the molecules of the material are fused together using the heat through a laser. SLS materials are not as diverse as those used in FDM and SLA, but they provide distinct advantages over these two such as isotropic strength in the case of the former and self-supporting structures in the case of the latter. SLS materials are great for complex geometries.

A relative newcomer to the 3D printing stage, metals have started to make a name for themselves. Metals such as stainless steel, aluminum, tool steels, nickel alloys and titanium have all been adopted for additive manufacturing processes such as metal FDM, binder jetting and powder bed fusion. Metal 3D printing does require more expensive and specialized equipment, but the result is metal parts that are more complex and robust.

The materials used in 3D printing are as diverse as they are unique, while at the same time constantly evolving. New materials are constantly being developed, which opens more doors for 3D printing to make an impact in a wide range of industries. Choosing the right material for your application can be difficult. We recommend you start by looking at the performance of the printed part you hope to achieve and narrow down your list to materials that can meet these specifications. If you are struggling choosing a material, our team at Beckatt Solutions is available to help. Contact us and let us help find the best 3D printing material for your project.