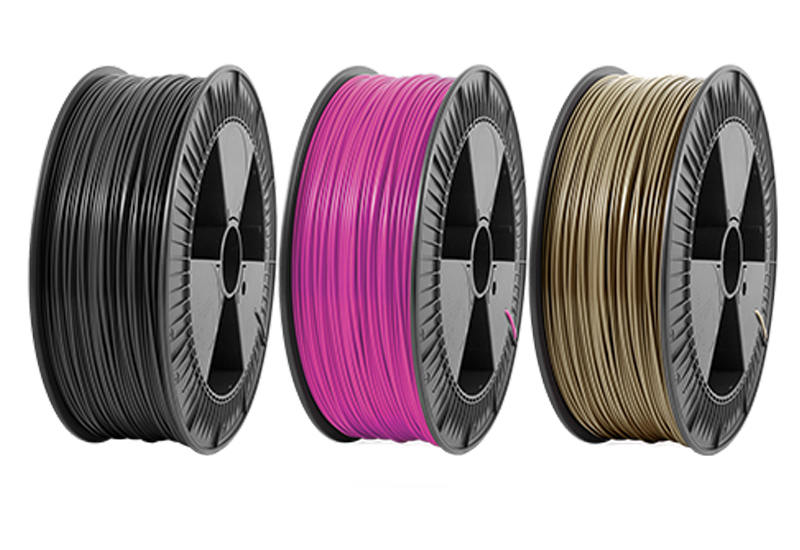

3DP ABS

3DP ABS

ABS 3D Printer Filament is an extra strong impact-resistant filament ideal for 3D printing of solid printed products. Due to the process stability and physical features of Acrylonitrile Butadiene Styrene it is a widely used thermoplastic polymer in industry. The material is also very light and durable. This makes ABS particularly suitable for tools, toys and all kinds of utensils. Printed at a slightly over-average temperature for ABS, this filament gives extra strong 3D print results.

About 3D Platform Materials:

3D Platform 3D printers utilize an open market platform, which is capable of printing most materials created for Fused Filament Fabrication (FFF).

Materials must meet the following criteria:

– The material type/shape matches the extruder (e.g. filament or pellets).

– The diameter of the material matches the diameter of the extruder (typically 1.75, 2.85 or 6.0 mm).

– The melting point (“print temp”) has a melting point that is equal to or less than that of the extruder (typically 290°C).

– The maximum bed temp (typically 145°C) is within the limits of the material.

– The air temp (sometimes called “chamber” or “oven” temp) of the machine is within the limits of the material.

This includes, but not limited to PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), Nylon, Ninja Flex, HIPS (High Impact Polystyrene), TPU, Wood or Metal filled materials, Nylons, some Polycarbonate materials. Note: Some materials may require increased bed and nozzle temperatures, as well as additional ventilation. To ensure print quality and an extend printer nozzle life cycle, we strongly recommend using consistent, good quality filament.