UltiMaker PVA Removal Station

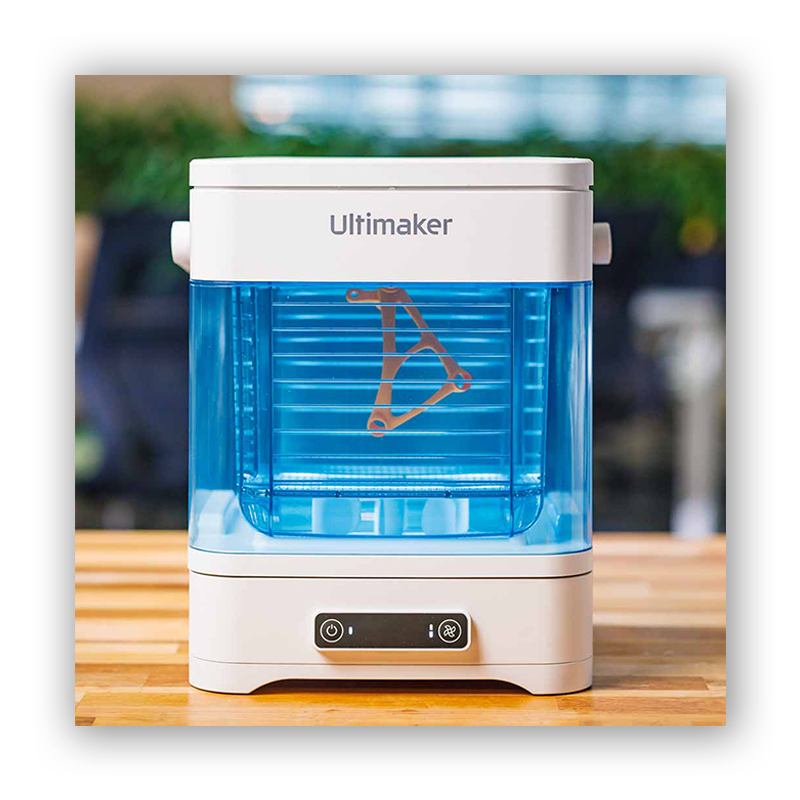

Ultimaker PVA Removal Station

Simple post-processing. Faster parts.

Make printing complex designs faster and easier. The Ultimaker PVA Removal Station dissolves support material quickly and effectively, keeping operator time to a minimum and increasing productivity.

Remove PVA up to 4x faster

Shrink your post-processing time

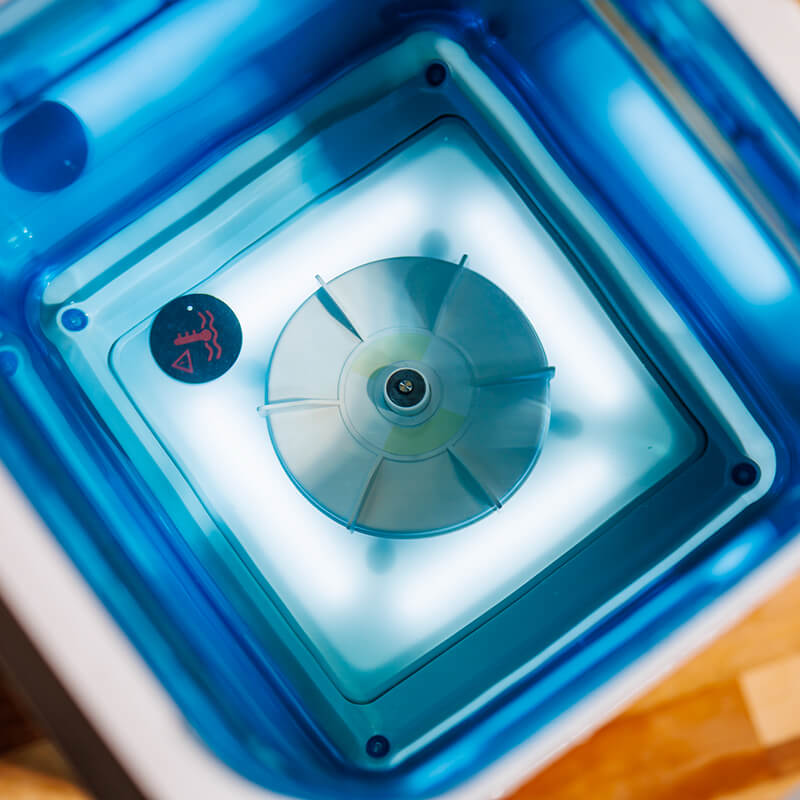

High-speed water circulation driven by a magnetic rotor removes PVA up to four times faster than motionless water, even from hard-to-reach cavities. So you have your parts post-processed and ready to use as soon as possible.

Rapid prototyping just got faster. And easier.

Low effort, higher productivity.

Rotor-powered water circulation

Choose 100 or 225 RPM circulation depending on the fragility of your part. Every two minutes, the rotor changes direction to push water evenly against the model.

Prints stay safe and submerged

A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

Easy to monitor progress

A transparent, illuminated container lets you easily follow the PVA removal process and see when your part is ready. Plus, a saturation indicator shows when to refresh the water.